On Monday, October 24, at the Gdańsk Remontowa Shipyard production of the first Ro-Pax ferry, construction number 101, for Polskie Promy, which will be operated by Unity Line, owned by Polska Żegluga Morska, has started.

As Krzysztof Gogol, advisor to the

managing director of Polska Żegluga Morska (PŻM) informed, the

event was attended by, among others Grzegorz Witkowski,

Undersecretary of State in the Ministry of Infrastructure, Andrzej

Wróblewski, CEO of PŻM, Adam Ruszkowski, President of the

Management Board of Remontowa Holding SA, Michał Habina, President

of the Management Board of Remontowa S.A., as well as representatives

of banks and insurance companies, classification societies,

institutions and companies involved in project and shipyard workers.

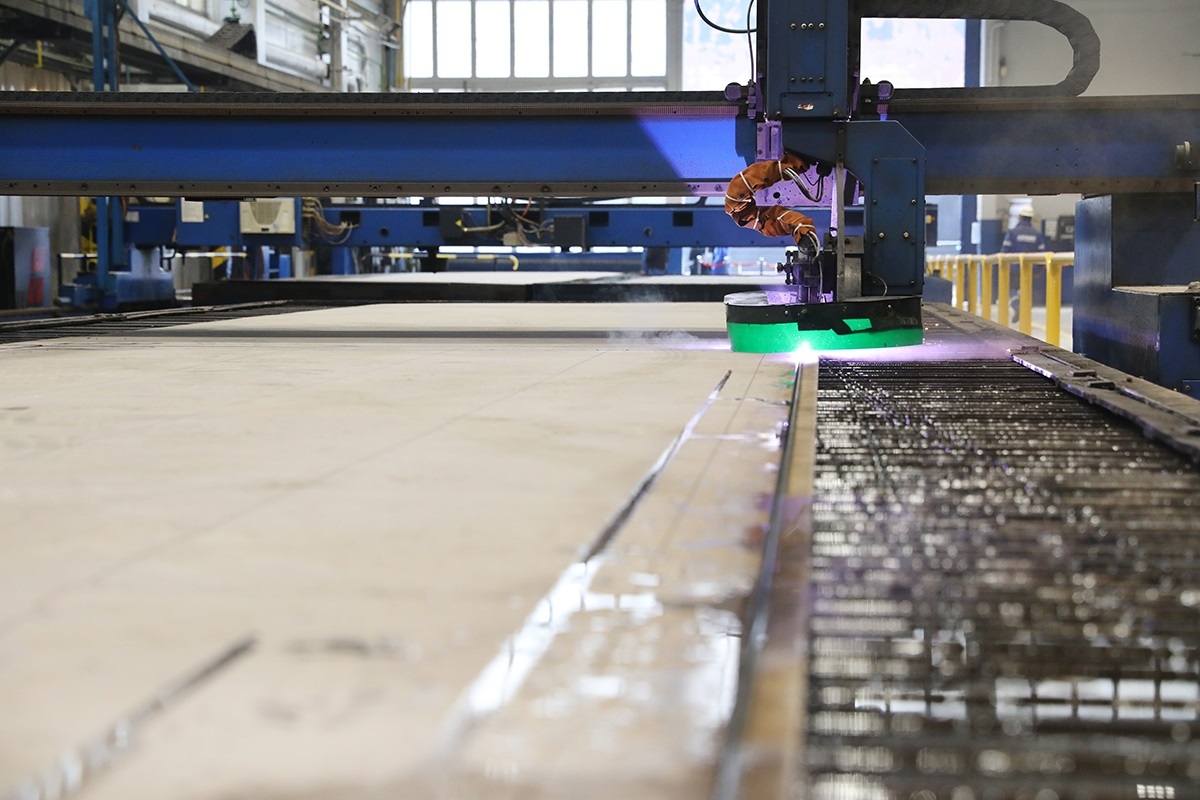

Cutting the first sheets means the

start of the technological process of ferry production in the

shipyard. They were made in plasma technology using a CNC cutter with

a 3D head, enabling cutting steel and metal alloys (aluminum,

stainless steel) with simultaneous edge bevelling.

This device produces a beam of

high-energy plasma with a temperature of up to about 30,000. st.

Celsius. It is one of several techniques for processing steel

elements used in shipyards of the Remontowa Holding group, enabling

fully automated, precise, efficient and fast cutting.

- Today, we are starting an

important phase of the production process of the first of the ferries

for Polish shipowners. It is a strategic undertaking aimed at

defending and maintaining the market position of domestic ferry

companies in the changing conditions of shipping in the Baltic Sea.

The new vessels, completely and from scratch, have been designed for

the service in the Baltic Sea area. They have a chance to meet the

challenges posed and bring an effect in the form of strengthening the

position of Polish shipping companies. The investment has a strong

ownership and operator base, including the State Treasury, PŻM P.P.

Capital Group, PŻB S.A. Capital Group. The construction of new

ferries with the participation of the State Treasury will allow,

among others, on the increase in the value of the shares of Polish

carriers on the Baltic market, employment of 800-1200 people directly

at the construction site, and at a later stage also ensuring constant

revenues for domestic repair shipyards for the next 30-40 years -

said Maciej Furmański, president of Polskie Promy.

- Today we are witnessing the

commencement of the physical construction of the first of the ferries

ordered from the Gdańsk Shipyard Remontowa by Polskie Promy. In the

near future, this vessel will operate under the name of Unity Line,

belonging to the Polska Żegluga Morska Group, and will open a

completely new chapter in Baltic shipping in terms of modern

technical standards and environmental friendliness. As a company with

over seventy years of experience in operating on the international

shipping market, we are able to appreciate a reliable business

partner, which is what the Remontowa Group is for us, a brand known

all over the world for its reliability and high standards of service.

We are also glad that the Polish shipowner will have ships built in

the Polish shipyard in his fleet. So we ask shipyard workers to put

the nameplate with the name of the manufacturer in a visible place,

because we will be very proud of it - said Andrzej Wróblewski, the

managing director of Polska Żegluga Morska.

- Less than a year after signing

the contract, after months of intensive preparations in the field of

design, financing, equipment and logistics of deliveries as well as

the organization of the production process, we started the

construction of the first ferry. This is a great moment for us -

shipyard workers. Our competences and vast experience, the knowledge

of our engineers and constructors, accumulated over the years in our

group's shipyards, will now be used to strengthen the competitiveness

of Polish shipowners, which will also translate into employment for

cooperative companies with whom we cooperate in the implementation of

this project. We are proud to be entrusted with the production of

these units. We also feel a great responsibility, because their

construction will be monitored by the entire ferry and shipbuilding

industry. The success of this project may mean a new opening on the

European shipbuilding market and strengthen the role of the Polish

industry as a supplier of low-emission, modern vessels - says Adam

Ruszkowski, President of the Management Board of Remontowa Holding

SA.

- We will build ferries according

to the technology that is well-tested in our company. After the

appropriate steel elements are cut out, they will be transported to

the prefabrication halls of flat sections, as well as semi-finished

products. At the prefabrication sites, they will then be assembled

into spatial sections, which will then be transported to the

construction site of the block. We will build blocks on a

semi-submersible barge, capable of lifting objects weighing up to

25,000 tons. After launching and putting the blocks into the floating

dock, they will be merged into the hull of the vessel - explains

Michał Habina, president of the Gdańsk Shipyard "Remontowa"

S.A.

The ferries are built under a

contract signed on November 26, 2021. Remontowa S.A. will build three

units for Polskie Promy. Two of the vessels will operate under the

colors of Unity Line, a subsidiary of PŻM, and one will be used by

PŻB. Part of the contract is a letter of intent containing the

option to build a fourth ferry.

They will be one of the most modern

vessels of this type in the Baltic Sea, powered by four liquefied

natural gas (LNG) engines with battery support in a hybrid system.

Instead of conventional propellers, each ferry will be equipped with

two azimuth thrusters at the stern and two bow thrusters at the bow,

which will greatly facilitate maneuvering in ports.

Each of the ferries will be 195.6 m

long and 32.2 m wide. The length of the load line is 4100 m and the

maximum speed will be 19 knots. The ferry will be able to carry 400

passengers, the crew will be 50 people.

The conceptual design, design and

executive documentation was prepared by the Remontowa Marine Design

and Consulting office from the Remontowa Holding group in cooperation

with the Ordering Party. Before commencing the production phase,

there were, inter alia, theoretical calculations and model tests of

the ship in the swimming pool of Centrum Techniki Okrętowej SA,

confirming the basic parameters, such as stability, hull shape,

draft, load capacity, load line length and speed.

The shipyard secured steel supplies

and signed contracts for equipment, including energy systems, motors

and thrusters, automation and control systems, heating and

ventilation as well as ro-ro equipment (enabling loading and

unloading).

The shipyard also obtained

performance bonds and payment guarantees, and concluded a line

agreement with a consortium of banks for guarantees and letters of

credit, securing deliveries related to the implementation of the

project.

The hull will be manufactured and

assembled in Gdańsk Remontowa Shipyard from sections built partly

with the participation of subcontractors, using the block

consolidation technology developed in the shipyard, using the dock

infrastructure. Each ferry will consist of six hull blocks and seven

superstructure blocks, which will be constructed from 265 separate

sections. One hull will weigh 11,000 tons.