Having the needs of our planet in mind, a few years ago a group of WUPROHYD’s engineers joined forces and created an innovative project of an ecological marine power plant, which apart from generating electricity from three independent renewable energy sources, can be used to produce green hydrogen and protect our sea shores. The most important component of the solution is the wave turbine which operates by using the circulation of water molecules.

Wave turbine

The wave turbine is a groundbreaking project of WUPROHYD design office, thanks to which one will be able to finally harness the huge energy resources from sea and ocean waves. This new RES can boast an estimated capacity of 2.5-3 TW, or 2,500,000-3,000,000 MW.

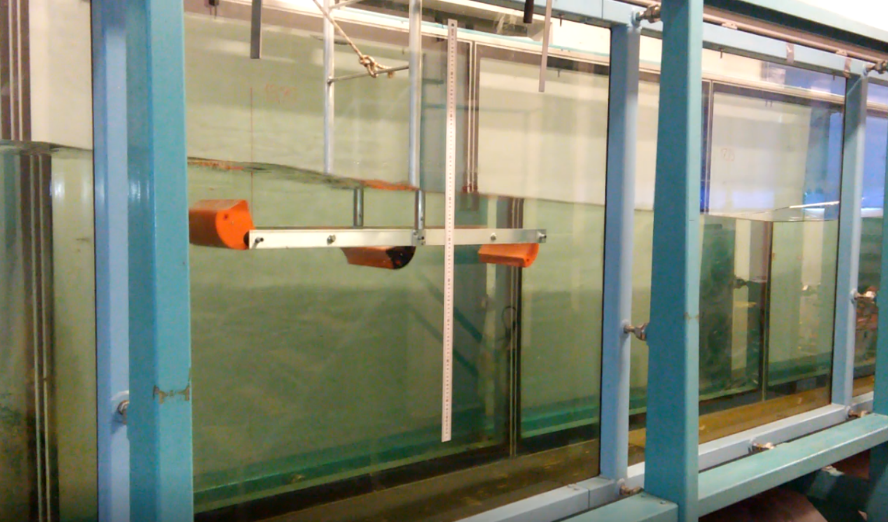

WUPROHYD design office, as the only one in Poland, has developed and patented this original prototype technology for the use of sea wave energy to produce electricity. Its main element comprises an ingenious wave turbine, i.e. a sea wave converter. At the current stage of the project, the technology development maturity level is RTL4 (according to the Technology Readiness Level), i.e. model tests were carried out for two different profiles of the turbine rotor. The tests confirmed the assumed rotational movement of the turbine rotor under the influence of the circular motion of water particles. The theoretical efficiency was determined at the level of approx. 7%. Therefore, the turbine can easily be used to directly drive power generators.

Wave turbine operation and construction

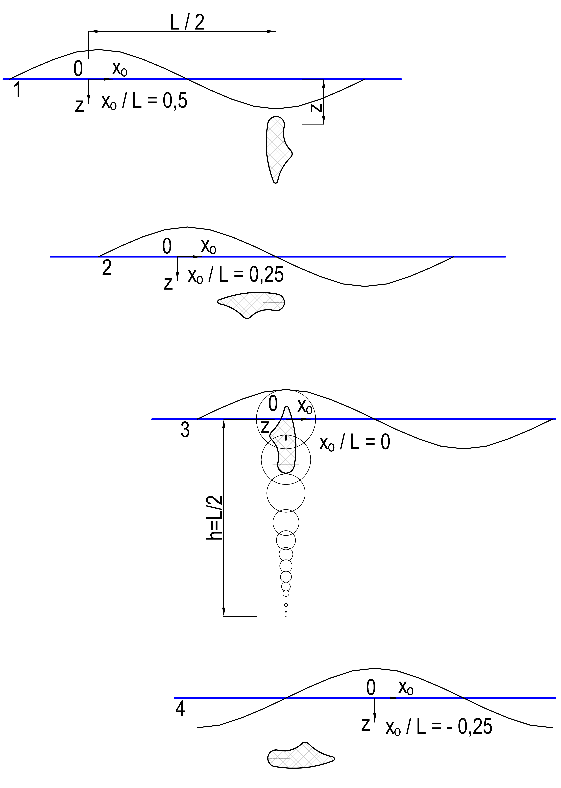

Fig. 2 - phase 3 shows the depth equal to half the wavelength h = L / 2, at which the undulations disappear. This means that most of the wave energy passes under the converter turbine, therefore a turbine efficiency of approx. 7% can be considered as satisfactory. This result is believed to be even higher, as model studies are planned to optimize the rotor profile. In order to increase the amount of energy obtained, it will be necessary to use several rows of turbines so that each successive row takes over some of the energy that passes under the previous one. This comes down to using the terminator converter in an attenuating configuration.

Obtaining the rotation of the turbine rotor under the influence of waves greatly simplifies the process of converting wave energy into electric energy. The turbine rotor can directly drive a power generator coupled to it by a simple gearing. This is a huge advantage of this solution over other existing converters, as they do not use the oscillating motion of wave water particles to drive power generators. Converters in use today convert wave motion into air or fluid motion, by means of which they move an air or water turbine, used to drive a power generator. As a result, converters currently available are very complex mechanical devices.

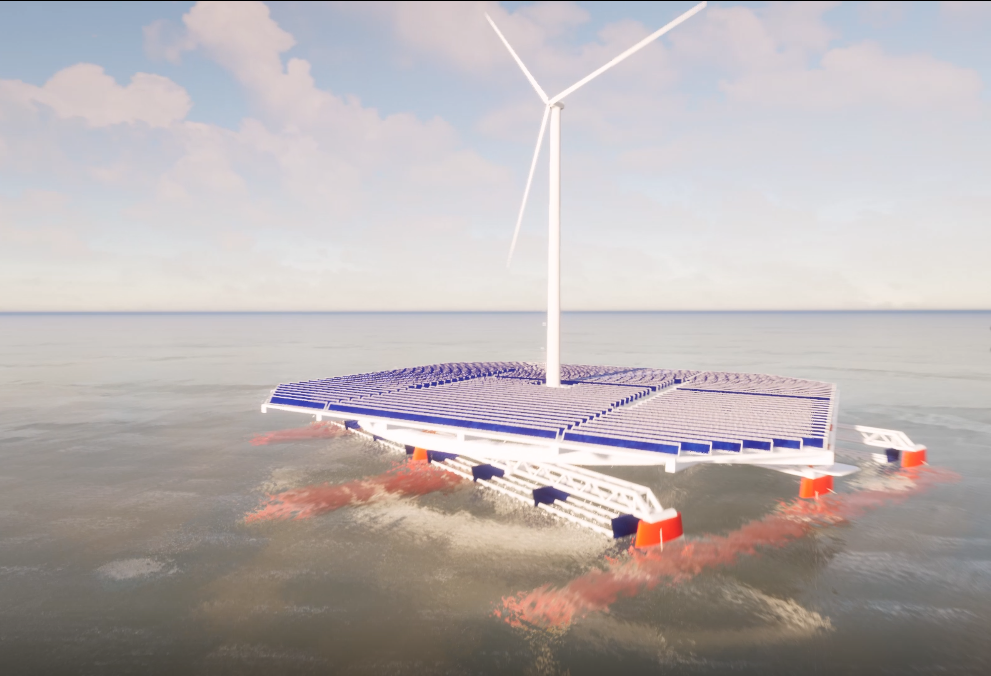

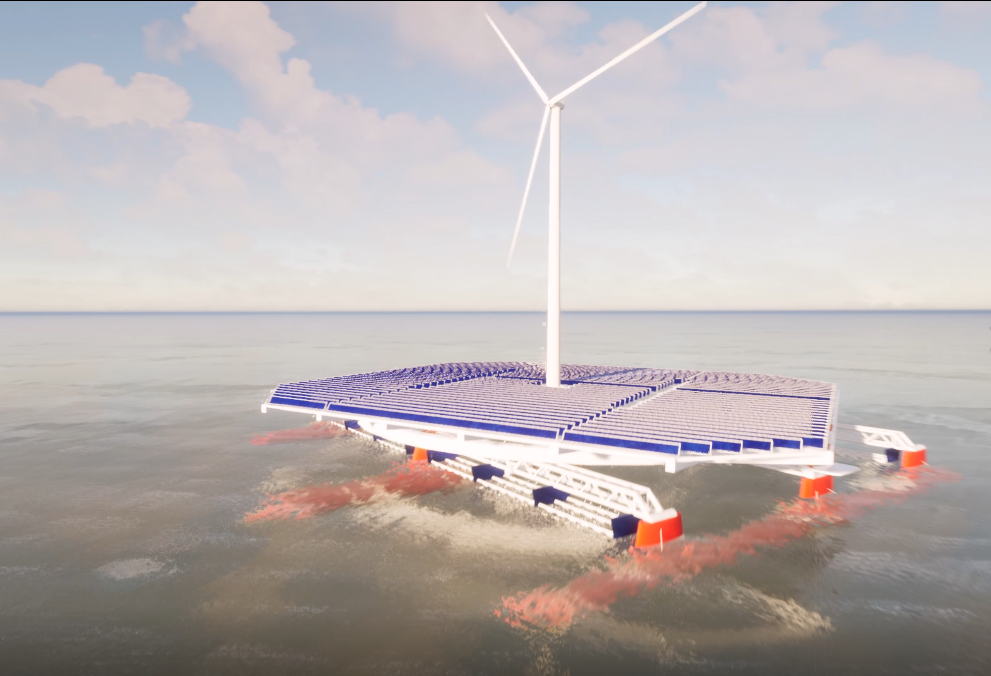

Energy Island - Eco-friendly offshore power plant

The invention is a floating object, LCA = ~ 250 m long and BCA = ~ 200 m wide, made of three underwater hulls with a total displacement of 78,000 T and a maximum draft of 20 m. The hulls are connected by frames and anchored to the reinforced concrete anchors lying on the seabed. In the space between the hulls, perpendicular to them, several rows of horizontal axes with converter wave turbines are located. Parallel alignment of the turbine axes to the wave crest (trough) is performed by automatic shortening and lengthening of appropriate mooring lines. The total capacity of the installed wave turbines for the conditions in the Baltic Sea is 1.6 MW. In order to take advantage of the capacity of the floating object, a sun-following rotating deck for solar panels with an area of 40,000 m2 and a wind turbine with a capacity of 12 MW or much more were installed. The capacity of one module of the ecological offshore power plant in the conditions of the Baltic Sea will amount to min. 17 MW, while in the North Sea, where the wave energy is much greater, the minimum capacity may even be as high as 34 MW.

Manufacturing technology

The load-bearing structure of the energy island is designed to be self-erecting and attached to reinforced concrete anchors. The advantage of this solution is that it can be folded, built and equipped as much as possible in a dry dock, which is ingenious, as taking into account its dimensions in an open mode - it would be impossible for the opened structure,. In addition, such a solution reduces the costs of installing the energy island at sea, limiting the use of very expensive floating cranes and tugs to the necessary minimum. In order to install smaller pieces of equipment, the structure is equipped with a crane that can move along the track mounted on its trusses. Moreover, the very high stability of the three-hull structure will reduce downtime caused by bad weather conditions related to work at sea. In practice, the adopted production technology requires only a pontoon and a tug for transporting the elements of equipment, which have not been installed in a dock. Reinforced concrete anchors are also designed to be floating. After being towed to their destination, they will be flooded by loading their ballast tanks with water. Anchors, if necessary, will be lifted by blowing the water from the ballast tanks with compressed air.