![Bufab opens quality laboratory [VIDEO] - MarinePoland.com Bufab opens quality laboratory [VIDEO] - MarinePoland.com](https://www.marinepoland.com/zdjecia/artykul/1605/6473/1200x0/2/bufab_1.jpg)

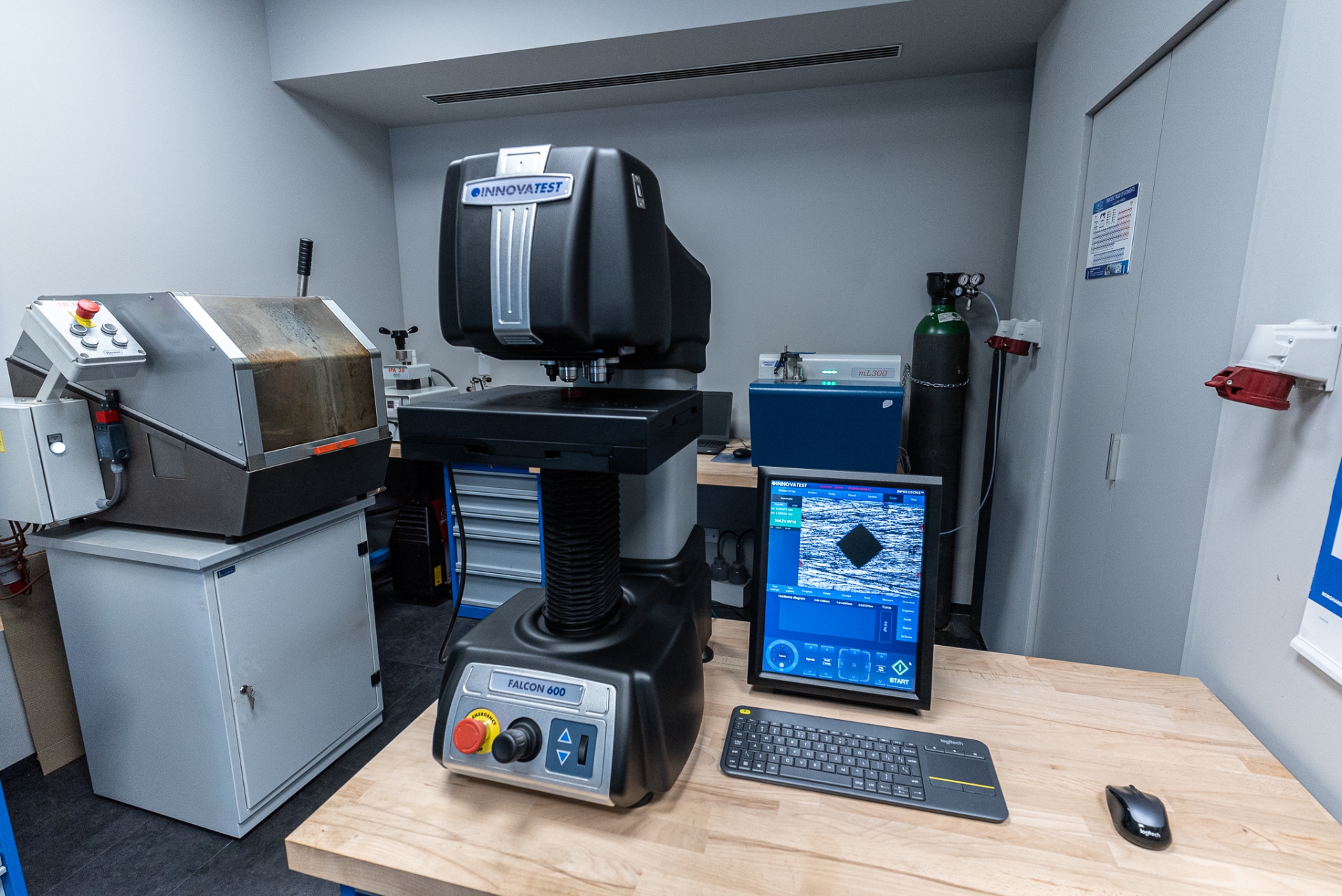

Bufab's Polish branch in Gdansk has opened a specialized quality laboratory. It can measure metal parameters such as straightness, the chemical composition of metals or the thickness of their plating. The laboratory is accredited and open to external customers.

Swedish

company Bufab distributes C-grade metal components needed for

industrial structures in industries such as rail, automotive, food,

and marine. This includes offshore wind farms.

- We decided

to open a quality laboratory to support our customers in technical

analysis and to have the ability to provide services externally -

said Michal Kostusik, Quality Manager at Bufab Poland. - Our

laboratory's testing methods are certified

- he added.

- Accreditation has allowed us to expand our

competences in measuring thickness, plating, hardness and chemical

composition of metals - added Tomasz Radka, Quality Engineer.

The

laboratory includes:

1. Innovatest hardness

tester - which tests hardness using the Vickers method,

2.

Vici Vision - which performs optical measurement of length and angle

with an accuracy of 5 microns in length and 3 microns in diameter,

3.

Fischer - measuring the thickness of galvanic coatings,

4. CMM

- performing coordinate measurement of length of angle using contact

heads and camera,

5. GNR

optical spectrometer - which examines chemical composition by spark

method under argon shielding.

Using the equipment available in

the Bufab laboratory, it is possible to measure such features as

hardness of metals and their chemical composition (hardness tester,

spectrometer), runout,

concentricity, cylindricity, straightness (Vici Vision) or

thickness of galvanic coatings (Fischer).